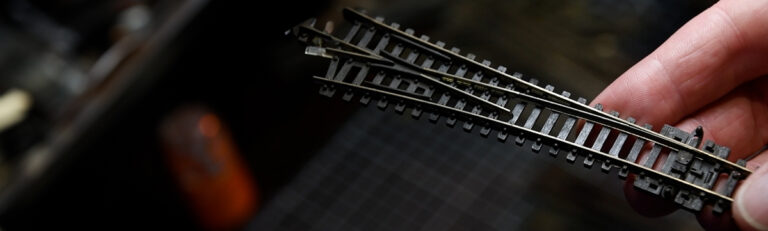

Having finished almost all the turnouts for the layout, including one of two curved turnouts, I decided to attach one to a length of track and run a car back and forth through the points to see how they worked. To my disappointment, every time the points were aligned to route the car to the diverging track, the rear set of trucks would ‘pick-the-point’ and hop off the rails. Confused, I carefully ran assorted cars back and forth through the turnout trying to determine what was going wrong.

I discovered that the leading truck of the car would glide smoothly across the points, but as the car moved along the track, the turning of the car meant that the rear trucks angled slightly to the outside rail. The sharp edge of the wheel was actually splitting between the point and the stock rail, despite the fact that the end of the point was razor-thin and seated in the notch of the stock rail. I dug out a commercial turnout and realized that area where the point met the stock rail was actually filed out quite deeply so that the point rail was recessed deeper than the thickness of the point. Solemnly, I took each of the points I had already built and one by one, disassembled the throw bar and painstakingly filed each rail until the point rested properly.

I discovered that the leading truck of the car would glide smoothly across the points, but as the car moved along the track, the turning of the car meant that the rear trucks angled slightly to the outside rail. The sharp edge of the wheel was actually splitting between the point and the stock rail, despite the fact that the end of the point was razor-thin and seated in the notch of the stock rail. I dug out a commercial turnout and realized that area where the point met the stock rail was actually filed out quite deeply so that the point rail was recessed deeper than the thickness of the point. Solemnly, I took each of the points I had already built and one by one, disassembled the throw bar and painstakingly filed each rail until the point rested properly.