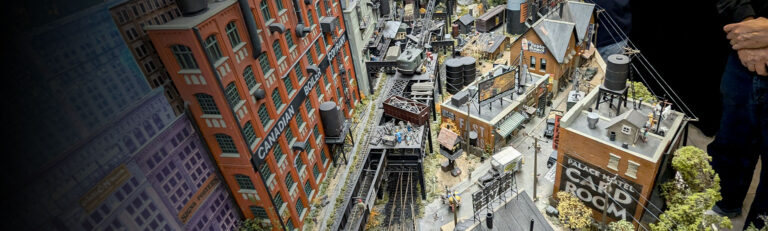

Progress on the WGR has been slow of late, but I’ve managed to finally finish laying the track.

Progress on the WGR has been slow of late, but I’ve managed to finally finish laying the track.

As mentioned in an earlier post, the switch machine dilemma was one factor responsible for the summertime pause. However, once I was able to finalize the switch machine design, progress ramped-up considerably.

I’ve yet to wire each of the turnouts and fix-up some of the roadbeds, but the track is done and initial tests suggest that everything is running smoothly.

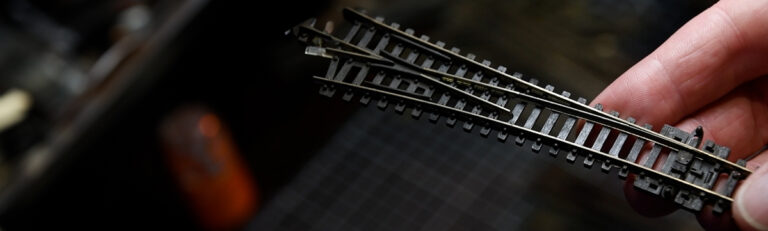

I feel it is worth mentioning that I modified my track laying technique for the WGR. I have traditionally used clear latex caulking as a track adhesive (impressed by the adhesion and ease of use) however the process of applying adhesive before the track can get rather messy when the track is adjusted (in order to join ends etc.). Shifting track once it be seated in the caulking forces caulk up between the ties – creating an annoying mess that must be cleaned up. In order to avoid this, sections of track with absolute positioning were fastened using caulk, and those sections that needed tweaking were pinned firmly in place and then covered in diluted white glue and wet-water – just as in ballasting.

I had some fears that the glue could ‘let-go’ once I start ballasting, however as I’m intent on painting the rails and ties, the track should stay in place – if by nothing more than the adhesive properties of the paint alone.