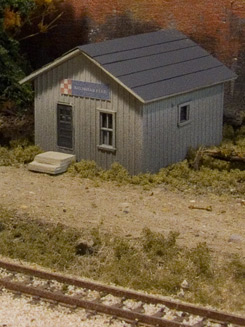

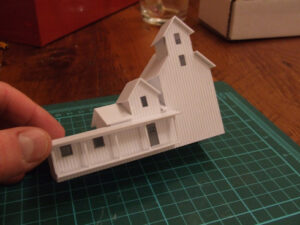

As noted in the previous post, the feed mill looked too desolate for my liking so I set out to add a small side structure. Working from the basic dimensions of the mill I constructed a simple office building – ensuring that I matched the roof pitch and basic form of the mill to ensure continuity. In two evenings I was able to complete the project (this scratch building stuff is getting easier!) and install it on the layout.

As noted in the previous post, the feed mill looked too desolate for my liking so I set out to add a small side structure. Working from the basic dimensions of the mill I constructed a simple office building – ensuring that I matched the roof pitch and basic form of the mill to ensure continuity. In two evenings I was able to complete the project (this scratch building stuff is getting easier!) and install it on the layout.

The suggestion was put forth that I attempt to reduce the thickness of the sandpaper by sanding the backing off of the paper in an attempt to make it thinner. The problem was the only sandpaper I had on hand was the 320 grit I was using to for the shingles themselves – after a minute of sanding I had barely removed the text on the backing paper so I cut my losses and quit (an experiment to follow up on later!). Despite this, the results were much better this time as I used CA to attach the shingles rather then white glue, and I was able to pinch the seams down tight against the building – improving the appearance dramatically. (I had used white glue for the other shingles so that if I was unhappy with the results I could remove the sandpaper and glue with just a bit of water.) I airbrushed the tarpaper roof and weathered the building, frosting the inside of the windows with a bit of paint to suggest dust.

I added the ‘Balinifad Feed’ sign to the office for a bit of colour, and to help reinforce the fact that this industry was not yet defunct. The sign was designed on the computer and printed to scale. I printed 6 copies of the sign and weathered them with the airbrush before cutting them out so I could select the best of the bunch. I believe weathering before cutting so prevented the paper from curling and the resulting sign sits quite flat against the building.

I’m very happy with how this turned out and I can now say that all of the structures are done!

One thought on “Finishing the Mill”

Scott says:

Again, very nice work!

The great thing about scratchbuilding is that you get the structure you want, that fits the space you have available, and it is unique to your layout. No one else has a structure exactly like it.

The next time you are out sandpaper shopping check out the cheapest stuff. It may be more acceptable for sanding, or peeling the backing layers off. The stuff I had wasn’t the cheapest, but it did separate quite easily.

Keep up the great work!

Scott