I spent the majority of the past week trying to clean the basement and get my airbrush working. I’m happy to report that the cleaning is done, and I finally have a usable airbrush! I’ve owned the same Badger airbrush for 17+ years and it’s worked great – the issue is the compressor. For as long as I’ve owned the airbrush I’ve also owned a very noisy compressor which I’ve been unable to use as the noise conflicts with the ‘tender sensibilities’ of the family. I finally visited the local TSC store and bought an 11-gallon air pig. It only takes about 2 minutes to fill the pig, and once filled, it lasts about 15-20 minutes. Finally, a silent airbrush!

I spent the majority of the past week trying to clean the basement and get my airbrush working. I’m happy to report that the cleaning is done, and I finally have a usable airbrush! I’ve owned the same Badger airbrush for 17+ years and it’s worked great – the issue is the compressor. For as long as I’ve owned the airbrush I’ve also owned a very noisy compressor which I’ve been unable to use as the noise conflicts with the ‘tender sensibilities’ of the family. I finally visited the local TSC store and bought an 11-gallon air pig. It only takes about 2 minutes to fill the pig, and once filled, it lasts about 15-20 minutes. Finally, a silent airbrush!

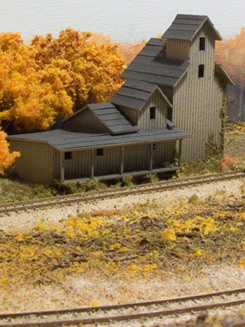

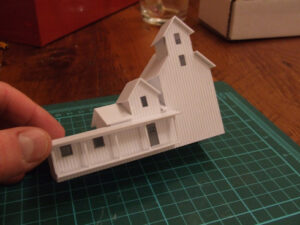

I didn’t bother to add much in the way of detail to the mill as I’m not too interested in making a hyper-detailed model at this stage – only a suitable industry facade. I decided that I would try modelling a tar paper roof and elected to use some 320 grit sandpaper. I had used sandpaper on one of the houses and was pleased with the results, however this time I wasn’t so pleased – the sandpaper is too thick. When I had applied it as a single sheet it worked well – suitable texture and good colour, however as I layered each course on the roof, the seam seemed too thick, likewise, the ‘yellow’ paper colour showed through on the edges. I finally had to airbrush the roof with a dirty black in an attempt to unify everything. Overall it looks fine, but I won’t use sandpaper again.

I weathered the building with an ink/alcohol wash and added a few light mists of dust, dirt and grime in an attempt to add a touch of weathering – nothing fancy, just enough to dull the colour and make the structure receded into its surroundings.

One of the ‘clever’ things I decided to do was to suggest the posts supporting the loading dock with groups of weeds. Gluing each of the posts under the overhang parallel and truly proved to be an exercise in extreme patience, so I cheated and suggested the posts with bushes.

I think I need another smaller office building to accompany the mill – it seems too isolated and desolate… Back to the drafting table!

0 thoughts on “The Feed Mill is (almost) Done!”

Scott says:

The feed mill looks great! I am impressed.

I had an idea while I was reading the part about the sandpaper being too thick. There is a technique for thinning signs printed on regular paper to make them look like they’ve been painted on a building. Perhaps a similar method would work with the sandpaper. Try sanding the paper backing down.

I had some sandpaper that starting separating on me resulting in a thin piece of paper with sand on it. I’m not sure why it did that. Perhaps it was really cheap stuff.

Anyway, that’s my $0.02 worth! Later!

Scott

Model Railroader says:

Thanks for the suggestion! Originally I thought I could soak the baking paper off of the sandpaper – however, I was using wet/dry sandpaper so 12 hours in a bowl of water did nothing… I wonder if I were to use regular sandpaper if I could remove some of the backing?

Kerry says:

Nice looking scene! I read a recent article about removing the backing of sandpaper, and it was as you described (soaking in water overnight). I’d give a finer grit (400) regular paper the soak….. If that doesn’t fly, then the sanding-of-the-backing method does work…..

Bill says:

Break down and get some 1000 grit paper at an auto body supply. The doghouse roof look will be gone.

Ron M says:

Hey that mill looks super to me. I’m just starting into N Scale and love all your tips and info.

Thanks much,

Ron