One of the challenges I’ve been trying to solve over the last few months is what to use as turnout controls on the WGR. While foam benchwork offers many design advantages (ease of construction, weight etc.), its solid structure complicates installing switch machines a practice greatly simplified in open-grid benchwork designs.

One of the challenges I’ve been trying to solve over the last few months is what to use as turnout controls on the WGR. While foam benchwork offers many design advantages (ease of construction, weight etc.), its solid structure complicates installing switch machines a practice greatly simplified in open-grid benchwork designs.

I wanted to avoid the use of manual turnout controls for appearance reasons only so I’ve spent the last while trying to develop a cheap/reliable controller. Likewise, the isolated frogs on the A55 switches need power routing an additional benefit of using the slide switches.

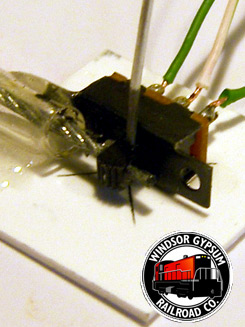

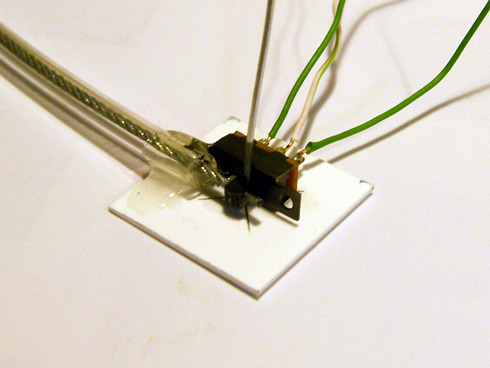

I developed my first controller using a slide switch to control the points, and a choke-cable arrangement to activate the switch. The choke-cable is made from small-diameter gas line tubing and aircraft cable. I assembled a temporary test switch and was happy with the results.

I refined the design further such that the controller consisted only of a slide switch epoxied to a small scrap of styrene, with the aircraft cable drilled/glued to the slide, and the point-control wire.

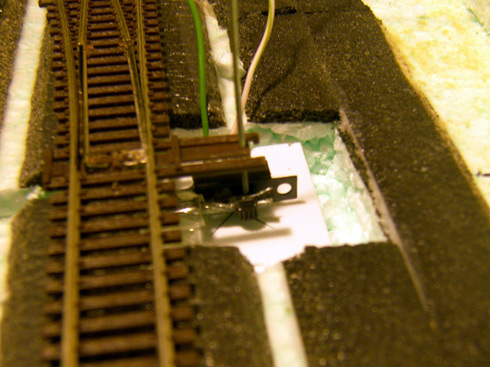

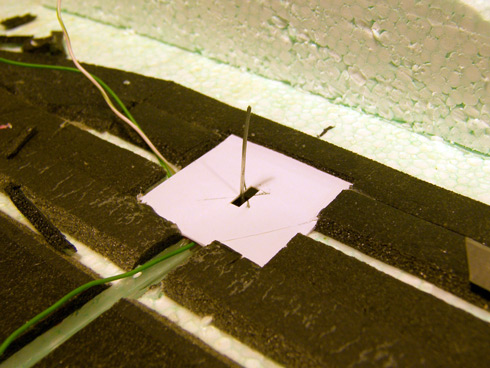

I installed the controllers by carefully carving a small 1″ deep cavity directly beneath each turnout throw-bar, and affixing the entire assembly into position using hot glue. Each of the control lines was embedded in channels carved in the foam, and covered with very thin styrene.

I am surprised at how well these controllers work. I’ve since finished the trackwork and the choke cables work flawlessly. Once I’ve installed the fascia, I’ll add some knobs to the ends of the controller cables.

Rather then write more on the assembly; I hope the pictures will suffice.

0 thoughts on “Simple Switch Machines”

Mike G says:

All of my micromodules have foam benchwork as well. I anchored my turnout machines, which are resin cast units of my own design that also use DPDT slide switches like yours, using plastic screw anchors. These are the yellow (or whatever colour) things you poke in a hole in your drywall to hang something. What I do, is poke a hole in the foam for the anchor then dribble a little Gorilla Glue on the anchor and shove it in the hole. After leaving it overnight, the anchor has become one with the styrofoam.

Also, since styrene is too expensive for me to use for anything but modeling, I use scraps of old thin wood panelling of the kind that was popular in the 1970’s. I just glue it to the foam with plain wood glue, held in place by duct tape while it is drying.

-mike

Model Railroader says:

Hey Mike – as always, thanks for the comment. The styrene I’m using is from ‘For Sale’ signs purchased at the dollar store. Cheap and thin!

ranulf says:

Hi Mike,

Is that piano wire which actually throws the turnout? What diameter is it, and does it need a bit of spring? Is the throw of the slide switch about equal to the throw of the turnout?

I like this idea, and want to do something similar.

Model Railroader says:

Ranulf,

The wire is simply small diameter steel wire. The travel in the switches was very close to that of the turnout, and as the toggle has a bit of play, it works out to be perfect.